ELEKTROLICHTBOGENOFEN

- Hochleistungs-EAF

- Teleskop-EAF

- EAF-Sonderausführungen

- Digitalisierung

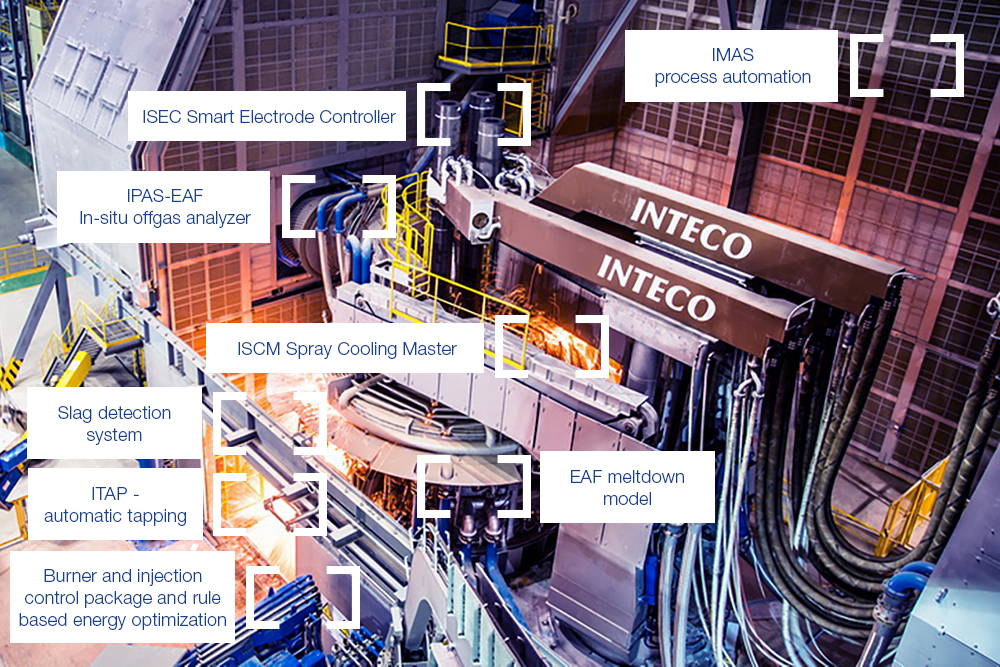

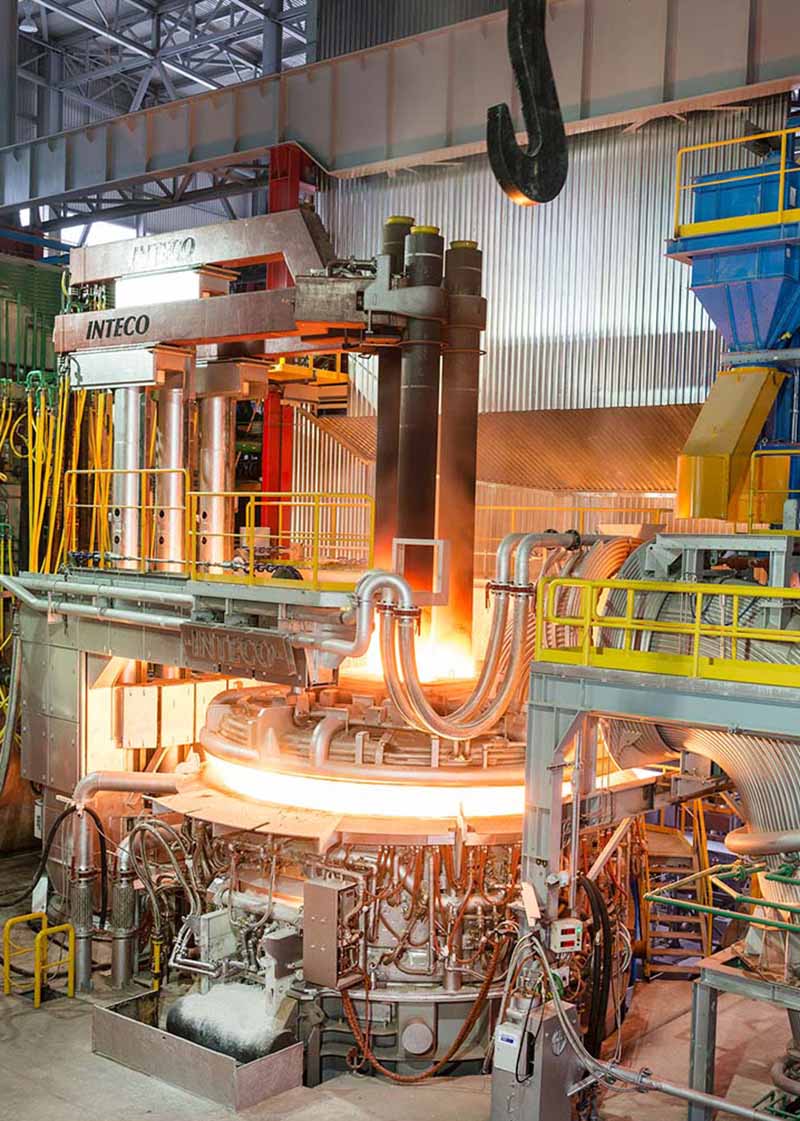

Unabhängig davon, ob Sie einen hochflexiblen Elektroofen für die Spezialstahlerzeugung oder ein ultraschnelles Einschmelzaggregat suchen – INTECO ist Ihr Technologiepartner für maßgeschneiderte Lösungen. Unsere Elektrolichtbogenöfen werden exakt auf Ihre Anforderungen zugeschnitten, mit einem Fokus auf eine stabile, stahlwerksgerechte und wartungsarme Konstruktion. Jeder Ofen wird speziell hinsichtlich des elektrischen und chemischen Energieeintrages auf die vorhandenen Einsatzstoffe und die zu produzierenden Stahlgüten hin optimiert.

Der Vorteil für unsere Kunden liegt auf der Hand: niedriger Energie- und Feuerfestverbrauch, sowie kurze Abstichfolgezeiten.

Für Kunden, die Lösungen für die speziellen Anforderung der CO2-neutralen Stahlerzeugung suchen, bieten wir innovative Lösungen für integrierte Hüttenwerke an, wie INTECOs Twin-EAF an. INTECOs maßgeschneiderte Designs ermöglichen einen flexiblen Einsatz verschiedener Rohmaterialien. So sind praktisch alle Kombinationen realisierbar, von 100% Schrotteinsatz bis hin zu 100% DRI/HBI- und sogar von bis zu 60% flüssigem Roheisen.

INTECOs Chemical Energy Package und INTECOs Smart Electrode Controller garantieren die höchste Performance für jeden Elektroofen. Darüber hinaus ermöglichen INTECO PTIs Brenner den Einsatz von Wasserstoff als Energieträger.

Unsere Technologie – Ihr Vorteil

- EBT oder Schnauzenabstich

- Stromführende Tragarme (Kupferplattiert oder aus Aluminium)

- Elektrodensprühkühlung

- Deckel- und Gefäßschnellwechselsystem

- ISEC Eletrodenregler

- INTECO PTI Chemical Energy Package

- INTECO PTI Swing Door

- IMAS Process Automation

- Primetals Technologies Active Power Feeder

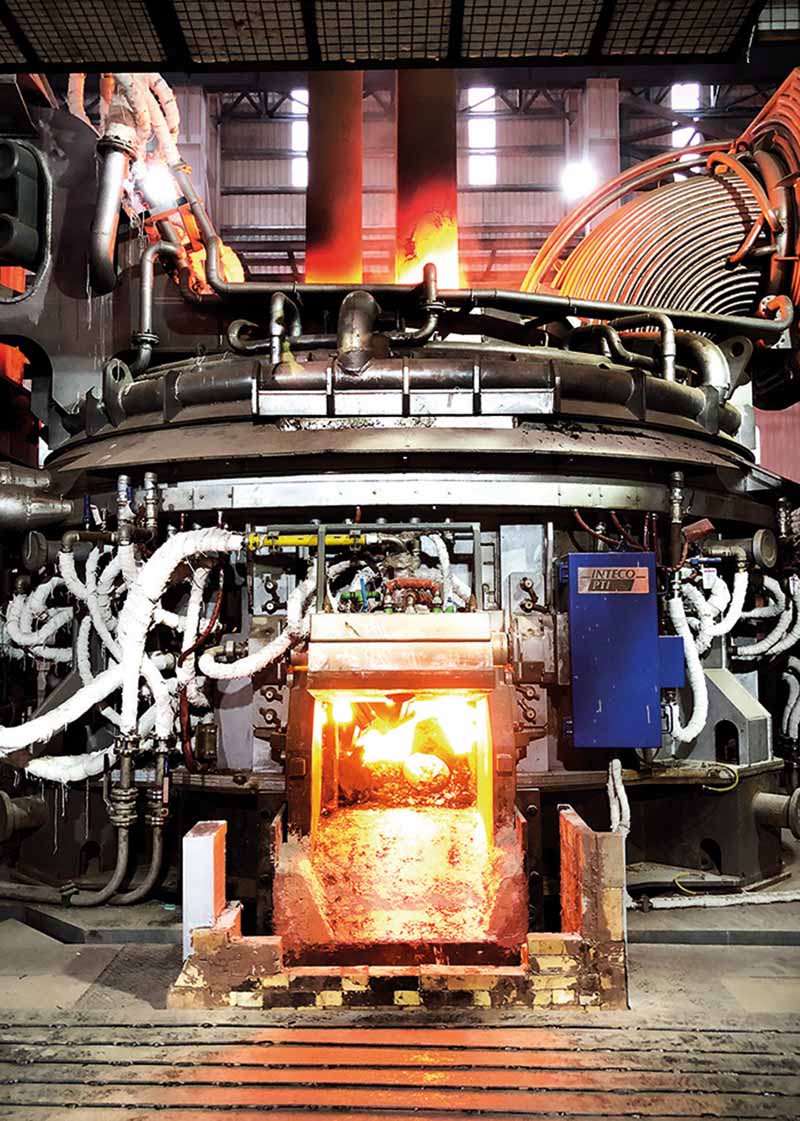

INTECO Fuchs’ Teleskop-EAF ist ein revolutionäres Konzept zur in-situ Schrottvorwärmung. Im Vergleich zu herkömmlichen Systemen kann unser Teleskop-EAF den elektrischen Energieverbrauch um bis zu 40kWh/t senken.

Dank der Teleskopfunktion ermöglichen wir eine Ein-Korb-Chargierung ohne erhöhtes Risiko von Elektrodenbrüchen, selbst bei Schrottdichten unter 0.5t/m³. Die bekannte Dioxinbildung im Abgas bei herkömmlichen Elektroöfen mit Schrottvorwärmung kann durch den Einsatz des INTECO Fuchs‘ Teleskop-EAF vollständig vermieden werden. Zusätzlich ist der INTECO Fuchs‘ Teleskop-EAF durch das Konzept der Ein-Korb-Chargierung das einzige Schmelzaggregate, dass eine effektive in-situ Schrottvorwärmung für die Spezialstahlindustrie ermöglicht.

Unsere Technologie – Ihr Vorteil

- INTECO Fuchs‘ Teleskop-Hubportal

- Teleskop-Obergefäß ausgelegt für Ein-Korb-Chargierung

- EBT oder Schnauzenabstich

- Stromführende Tragarme (Kupferplattiert oder aus Aluminium)

- Elektrodensprühkühlung

- ISEC Eletrodenregler

- INTECO PTI Chemical Energy Package

- INTECO PTI SwingDoorTM

- IMAS Process Automation

Unsere Elektrolichtbogenöfen für kleine Chargengrößen eignen sich perfekt für Entwicklungsarbeiten oder für Kleinserienproduktion. Dank des sorgfältigen Designs und der Ausführung kleiner Ofengeometrien können auch für Mini-EAF niedrige Verbrauchswerte und optimale metallurgische Prozessbedingungen sichergestellt werden. Die INTECO PTI Mini JetBOx™ sowie das INTECO PTI Mini SwingDoorTM wurden speziell für die Anwendung in kleinen Elektrolichtbogenöfen entwickelt.

Neben den klassischen Lichtbogenöfen für die Stahlindustrie bietet INTECO auch maßgeschneiderte Lösungen für Eisen- und Stahlgießereien an. Das Produktportfolio wird durch Elektroreduktionsöfen für Ferrolegierungen und Siliziummetall sowie durch Sonderausführungen zur Herstellung von hochschmelzenden Materialien (Schmelzmagnesit, Elektrokorund, etc) abgerundet.

Der bewährte ISEC-Elektrodenregler sowie die IMAS Process Automation kommen auch bei Mini-EAFs zur Anwendung.

Reduktionsöfen für die Herstellung von Ferrolegierungen

Reduktionsöfen für die Herstellung von Ferrolegierungen

Elektroöfen für geschmolzenes Magnesit

Elektroöfen für geschmolzenes Magnesit

Unsere Elektrolichtbogenöfen für kleine Chargengrößen eignen sich perfekt für Entwicklungsarbeiten oder für Kleinserienproduktion. Dank des sorgfältigen Designs und der Ausführung kleiner Ofengeometrien können auch für Mini-EAF niedrige Verbrauchswerte und optimale metallurgische Prozessbedingungen sichergestellt werden. Die INTECO PTI Mini JetBOx™ sowie das INTECO PTI Mini SwingDoorTM wurden speziell für die Anwendung in kleinen Elektrolichtbogenöfen entwickelt.

Neben den klassischen Lichtbogenöfen für die Stahlindustrie bietet INTECO auch maßgeschneiderte Lösungen für Eisen- und Stahlgießereien an. Das Produktportfolio wird durch Elektroreduktionsöfen für Ferrolegierungen und Siliziummetall sowie durch Sonderausführungen zur Herstellung von hochschmelzenden Materialien (Schmelzmagnesit, Elektrokorund, etc) abgerundet.

Der bewährte ISEC-Elektrodenregler sowie die IMAS Process Automation kommen auch bei Mini-EAFs zur Anwendung.

Submerged arc furnace for ferro alloy production

Submerged arc furnace for ferro alloy production

Electric furnace for fused magnesite

Electric furnace for fused magnesite

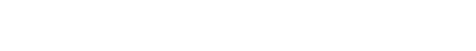

Digitalisierung und Smart Production sind die treibenden Kräfte für Entwicklung und Veränderung in der Stahlbranche. Bei INTECO bieten wir Ihnen nicht nur erstklassiges Engineering im Anlagenbau, sondern auch maßgeschneiderte digitale Lösungen, die den anspruchsvollen Anforderungen unserer Kunden gerecht werden. Überwachen Sie Ihre Produktion effizienter und nutzen Sie die gesammelten Informationen für Anpassungen und Fortschritt.

INTECO’s Smart Electrode Controller (ISEC) was developed to meet modern furnace operation requirements especially Electric Arc Furnaces and Ladle Furnaces. Designed to control different arc operations, the ISEC can also be applied to other types of electric furnaces for non-ferrous metals, ferro-alloys and even slag heating. The ISEC is based on a state-of-the-art embedded controller that allows high sampling rates and precise computations/calculations of all electric/power values in real time. For flexible operation and fast diagnostics, a modern web-based visualization system is integrated. It offers direct access to advanced information such as working points, control stability, arc lengths, and energy input. Moreover, the ISEC comes with advanced features such as automatic dip testing, automatic valve scaling, adaptive set point control, and a fuzzy logic based foaming slag manager. Standard interfaces such as PROFINET, PROFIBUS or Ethernet/IP facilitate simple integration in new or retrofit projects.

IMAS-PA-EAF provides advanced top-down process guidance through dynamic or static treatment planning and integrated optimization tools. Process supervision is massively improved by the cockpit view and integrated real-time process models. IMAS provides instant real-time information and alerts, based on which the operators can control and steer the process just-in-time. The heat-based data recording stores sensor data, including complex information such as video streams, allowing observation of real-time data for quality assurance and process improvement.

INTECO’s Process Analysis System (IPAS-EAF) directly measures hot and dusty gases and therefore opens new ways to monitor and control the steel making process. The infrared system helps to maintain plant availability, saves energy and helps to protect the environment. Designed for the application in the ultra-harsh environment of an EAF, it provides real-time, in-situ, simultaneous measurement of temperature, CO, CO2, and. The integrated flow measurement system is a single channel solution, which works according to a patented correlation principle. The system is also capable of measuring flow by the flight time of unique signal patterns created by particles contained in the gas. As the principle is time-based, it is accurate and drift-free over the entire lifespan. It seamlessly integrates and enhances the function of the EAF meltdown model.

The INTECO spray cooling master (ISCM) is an automatic state-based cooling optimization to cool down electrodes by air-mist to extend the service life of electrodes. The integrated filter system includes an automatic backwash function to clean the filters automatically and an instrumented pipe assembly to check the pressure and temperature.

The slag detection system controls the amount of pour-over slag in the ladle. The tapping process is monitored by a thermographic (IR) camera. The brightness depends on composition, surface properties and temperature. Even if steel and slag temperature are similar, differences in composition and surface properties allow the system to distinguish between them. The camera is housed in a water-cooled enclosure that is equipped with purged compressed air. This set-up continuously monitors the tapping area with a special detection software that controls the amount of slag until the pre-set alert levels are reached. The software records the entire tapping process for further analysis from start till end.

The automatic tapping system (ITAP) automatically lifts the electrode columns to the tapping position as soon as an operator triggers it. Controlled EAF inclination helps to maintain a defined tapping speed, which is the parameter that drives the function and automatically considers the refractory lifetime. After tapping is completed, the EAF can automatically return to a horizontal or deslagging position. If required, a high-resolution (HD) camera can be installed in a water-cooled jacket to provide a video stream to the control room, allowing operators to monitor the tapping process directly.

Our burner and injection control package ensures safe and optimal energy input for a stable and reproduceable melting process. The optional rule-based energy optimization provides an additional control loop enhancing the dynamic power profile with a fuzzy logic engine to finetune furnace set points for minimum electrode consumption, refractory wear, and energy usage. This type of optimization allows to switch directly between production needs such as maximum melt-down performance or minimal operation costs. Moreover, it perfectly integrates with INTECO’s EAF meltdown model and INTECO’s Smart Electrode Control (ISEC).

The EAF Meltdown Model is designed to optimize the electric power profile and electric arc furnace operation by monitoring and predicting the thermal and metallurgical evolution of the heat state. It helps with predictive control, operator assistance, online process optimization, understanding the underlying physical processes, and estimating parameters that cannot be measured directly. It achieves this by detailed modelling of the furnace’s different control volumes including liquid, solid, and gaseous phases. The non-linear model makes it possible to represent complex interrelated phenomena, including the estimation of the visibility of the electric arc and arc efficiency for melting and heating as well as physical modelling principles such as mass and energy balances. It tracks the temperatures, total masses and masses of individual components in both the solid and liquid phases of steel and slag within the furnace.

Top-Lanzen werden als Notspüllanzen (falls der Spülstein blockiert ist), oder zum Einblasen von Reaktionsmittel (z. B. CaO, C, CaC2) je nach metallurgischen Anforderungen verwendet.

Temperaturmessungen und Probenahmen, die von Robotern oder Manipulatoren durchgeführt werden, gewährleisten konstante und reproduzierbare Ergebnisse. Darüber hinaus reduzieren automatische Probemanipulationssysteme notwendige manuelle Arbeitsschritte.

Drahteinspulen ist die präziseste Methode, um kleine Mengen von Desoxidationsmitteln und Legierungen in die Schmelze einzubringen. INTECO liefert Drahteinspulmaschinen zusammen mit dem gesamten Drahtführungssystem vom Drahtbundlager zur Maschine.

Ein sorgfältig konzipiertes Hochstromsystem (trianguliert mit minimaler Asymmetrie und Impedanz) in Kombination mit der INTECO-Elektrodenregelung gewährleistet einen niedrigen Energieverbrauch und hohe Heizraten.

Unabhängig von der Ausführung, ob stehend oder abgehängt, ist das Elektrodenhubsystem darauf ausgelegt, den verfügbaren Platz optimal zu nutzen. Schwenkportale werden bei Doppelpfannenöfen mit zwei Behandlungspositionen verwendet. Das wartungsfreundliche Führungssystem für die Elektrodensäulen gewährleistet eine einfache Einstellung der lebensdauergeschmierten Führungsrollen.

INTECO bietet den wassergekühlten Ofendeckel in verschiedenen Ausführungen an, darunter die bewährte Rohr-an-Rohr-Konstruktion oder aber auch mit glatter Innenseite, um Anbackungen zu minimieren. Das patentierte Deckeldesign garantiert minimale Reoxidation und einen geringen Elektrodenverbrauch.

Der Pfannenwagen bewegt die Pfanne zwischen den Behandlungspositionen und kann mit einem Kipprahmen zum Abschlacken in Verbindung mit einem Abschlackstand ausgestattet sein. INTECOs am Wagen installierte Gaskuppler, ermöglichen eine vollautomatische Verbindung mit der Gasregelstrecke und erhöhen die Arbeitssicherheit dramatisch.

PROJEKTE

Gloria Material Technology

TianMa

Bastug Metallurgy

Metal Ravne

Grupo Frisa