LADLE FURNACE

- General information

- Design variations

- Our design – your advantage

- Digitalization

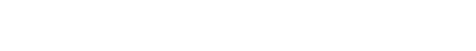

Ladle furnaces are increasingly being installed in basic oxygen plants as well as electric arc furnace melt mills. INTECO offers tailored solutions for every ladle furnace application. With a tailor-made design, INTECO’s ladle furnaces fit even the tightest spaces while also meeting the requirements of special steel plants with long, intensive metallurgical treatments as well as high performance, short-cycle treatments in BOF steel plants. Special attention is given to ensuring easy and low maintenance requirements to guarantee a long and trouble-free operation.

- Single or twin stand (with swiveling portal)

- Heat sizes from 6 to 300t

- Different roof designs available (pipe to pipe, flat inner surface, copper cladded)

- Standard or hanging portal system

- Ladle transfer car with optional tilting stool and weighing device

- Designed with gas or electromagnetic stirring system

- For steel plants, foundries, and ferroalloy plants

- Furnace roof with flat inner surface (steel plates or copper plated)

- Fast exchangeable guide blocks

- Automatic gas coupling system

- INTECO ISEC electrode control

- Easy access for maintenance and repair

- All auxiliary equipment from a single source

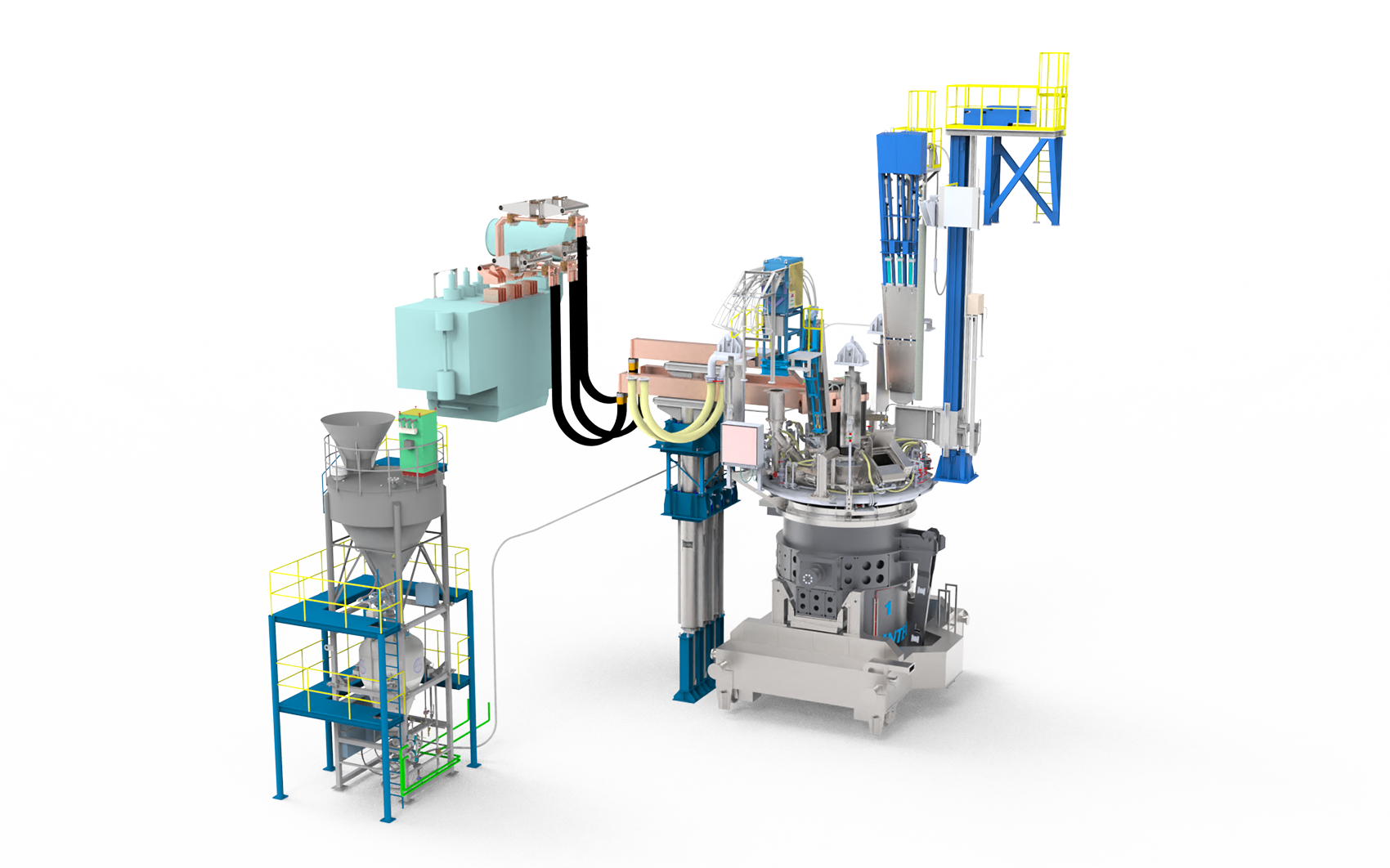

Digitalization and smart production are transforming the steel industry, driving development and change. At INTECO, we offer not only first-class engineering in plant construction, but also customized digital solutions tailored to our customers’ demands. Enhance your production with our digital solutions and utilize the collected data to make strategic adjustments and drive continuous progress.

INTECO’s Smart Electrode Controller (ISEC) was developed to meet modern furnace operation requirements especially Electric Arc Furnaces and Ladle Furnaces. Designed to control different arc operations, the ISEC can also be applied to other types of electric furnaces for non-ferrous metals, ferro-alloys and even slag heating. The ISEC is based on a state-of-the-art embedded controller that allows high sampling rates and precise computations/calculations of all electric/power values in real time. For flexible operation and fast diagnostics, a modern web-based visualization system is integrated. It offers direct access to advanced information such as working points, control stability, arc lengths, and energy input. Moreover, the ISEC comes with advanced features such as automatic dip testing, automatic valve scaling, adaptive set point control, and a fuzzy logic based foaming slag manager. Standard interfaces such as PROFINET, PROFIBUS or Ethernet/IP facilitate simple integration in new or retrofit projects.

The smart process camera is a retractable and therefore well protected optical system that directly streams a high-resolution video to the control room to ensure safe low-manpower operation. The optional thermal imaging variant provides a clear view through smoke and dust and serves for automatic stirring adjustment. Additional generated process information such as slag height and stirring eye detection enhances metallurgical model accuracy and safety.

INTECO’s Material Handling System Automation offers precise and time-critical alloying for all secondary metallurgy plants. Its recipe-based approach serves various technologies such as positive and negative weighing, shuttles, weighing bands, or hoppers and integrates micro-dosing systems and wire feeding machines. Moreover, it provides fallback modes for redundant feeding lines as well as sequential dosing of materials or material groups to add slag builders and alloys in the correct order.

The thermochemical model calculates oxide and element activities based on current process conditions and events, current heat state and energy losses and gains. In this context, IMAS modeling includes a thermophysical property library, reaction enthalpies, coefficients for interactions providing the necessary parameters, and coefficients to determine and calculate the activities.

The temperature model accounts for the temperature losses due to radiation and convection as well as the changes in temperature due to purging, material addition and heating. Temperature changes due to reactions are also taken into account and are therefore coupled with the basic thermochemical model. Both are not only used to calculate the actual heat state but also to predict take-over time and temperature.

IMAS-PA-LF provides advanced top-down process guidance through dynamic or static treatment planning and integrated optimization tools. Process supervision is massively improved by the cockpit view and integrated real-time process models. IMAS provides instant real-time information and alerts, based on which the operators can control and steer the process just-in-time. The heat-based data recording stores sensor data, including complex information such as video streams, allowing observation of real-time data for quality assurance and process improvement.

PROJECTS

thyssenkrupp Steel Europe

Columbus Stainless

voestalpine Stahl Donawitz GmbH

Saarstahl AG

Aperam