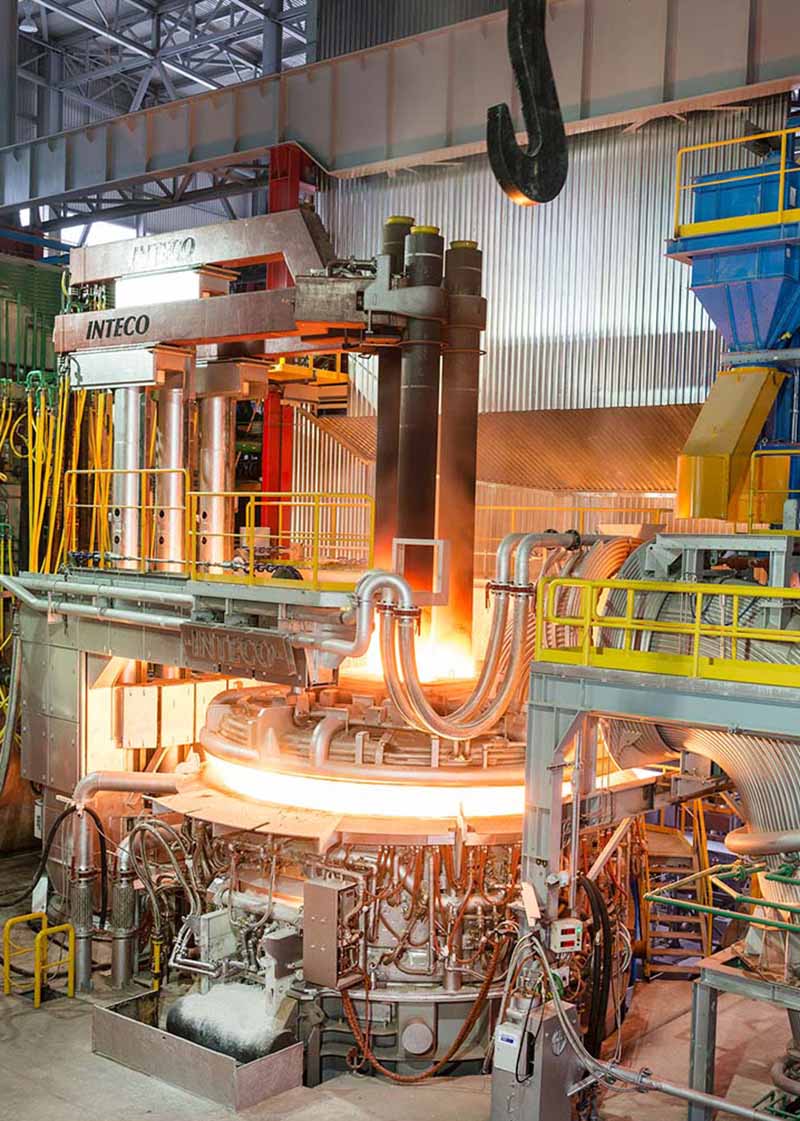

ELECTRIC ARC FURNACE

- High-performance EAF

- Telescope EAF

- EAF special designs

- Digitalization

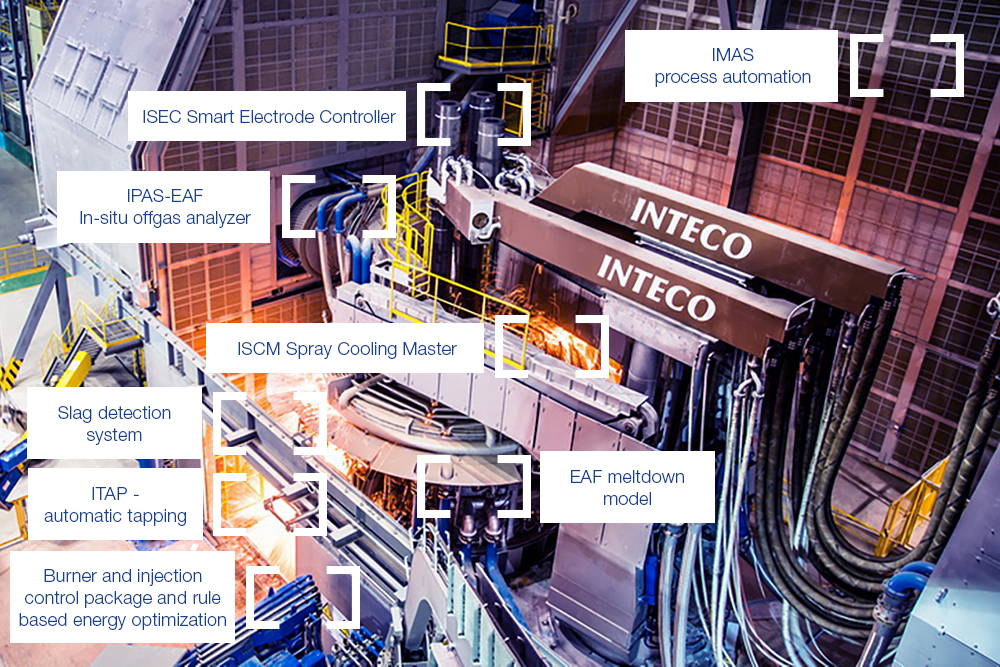

Regardless of whether you are looking for a highly flexible electric arc furnace for special steel production or an ultra-fast melting unit – INTECO is your technology partner for customized solutions. Our electric arc furnaces are tailored to your requirements, with a focus on a stable, steel mill-compatible and low-maintenance design. Each furnace is individually optimized for electrical and chemical energy input to suit the existing input materials and the required steel grades. The advantage for our customers is obvious: low energy and refractory consumption, as well as short tapping sequences.

For customers who are looking for solutions for the special requirements of CO2-neutral steel production, we offer innovative solutions for integrated steel plants, such as INTECO’s Twin-EAF.

INTECO’s tailor-made designs allows flexible use of different raw materials. Thus, almost any combination can be realized, from 100 % scrap to 100 % DRI/HBI and even up to 60 % hot metal. INTECO’s Chemical Energy Package and INTECO’s Smart Electrode Controller guarantee highest performance for every electric furnace. In addition to natural gas, INTECO PTI’s burners can use hydrogen as an alternative energy source.

Our Technology – Your Advantage

- Tapping systems with EBT or tapping spout

- Current conductive arms (copper-plated or aluminum)

- Electrode spray cooling

- Cover and vessel quick-change system

- ISEC electrode controller

- INTECO PTI Chemical Energy Package

- INTECO PTI Swing Door

- IMAS process automation

- Primetals Technologies Active Power Feeder

INTECO Fuchs’ Telescope EAF is a revolutionary concept for in-situ scrap preheating. Compared to conventional systems, our Telescope EAF can reduce electrical energy consumption by up to 40 kWh/t. Thanks to the telescopic function, we enable single-bucket charging without an increased risk of electrode breakage, even with scrap densities below 0.5 t/m³. The hazardous dioxin formation in the exhaust gas from conventional electric furnaces with scrap preheating can be completely avoided by using the INTECO Fuchs’ telescopic EAF. In addition, INTECO Fuchs’ Telescope EAF is the only melting unit that enables effective in-situ scrap preheating for the special steel industry thanks to its single-bucket charging concept.

Our Technology – Your Advantage

- INTECO Fuchs‘ Telescope portal

- Telescope upper shell for single bucket charging

- Tapping systems with EBT tap hole or tapping spout

- Conductive arms (copper-plated or aluminum)

- Electrode spray cooling

- ISEC electrode controller

- INTECO PTI Chemical Energy Package

- INTECO PTI SwingDoorTM

- IMAS process automation

Mini-EAF, electric reduction furnaces and special designs

Our electric arc furnaces for small heat sizes are perfect for use in development work or for small batch production. Thanks to the tailored design and small furnace geometries, low consumption values and optimum metallurgical process conditions can also be ensured for mini EAFs.

The INTECO PTI Mini JetBOx™ and the INTECO PTI Mini SwingDoorTM have been specially developed for use in small electric arc furnaces.

In addition to classic electric arc furnaces for the steel industry, INTECO also offers tailor-made solutions for iron and steel foundries. The product portfolio is completed by electric reduction furnaces for ferroalloys and silicon metal as well as special designs to produce refractory materials (fused magnesite, electro corundum, etc.).

The proven ISEC electrode controller and IMAS Process Automation are also used in mini EAFs.

Submerged arc furnace for ferro alloy production

Submerged arc furnace for ferro alloy production

Electric furnace for fused magnesite

Electric furnace for fused magnesite

Mini-EAF, electric reduction furnaces and special designs

Our electric arc furnaces for small heat sizes are perfect for use in development work or for small batch production. Thanks to the tailored design and small furnace geometries, low consumption values and optimum metallurgical process conditions can also be ensured for mini EAFs.

The INTECO PTI Mini JetBOx™ and the INTECO PTI Mini SwingDoorTM have been specially developed for use in small electric arc furnaces.

In addition to classic electric arc furnaces for the steel industry, INTECO also offers tailor-made solutions for iron and steel foundries. The product portfolio is completed by electric reduction furnaces for ferroalloys and silicon metal as well as special designs to produce refractory materials (fused magnesite, electro corundum, etc.).

The proven ISEC electrode controller and IMAS Process Automation are also used in mini EAFs.

Submerged arc furnace for ferro alloy production

Submerged arc furnace for ferro alloy production

Electric furnace for fused magnesite

Electric furnace for fused magnesite

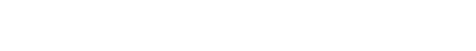

Digitalization and smart production are transforming the steel industry, driving development and change. At INTECO, we offer not only first-class engineering in plant construction, but also customized digital solutions tailored to our customers’ demands. Enhance your production with our digital solutions and utilize the collected data to make strategic adjustments and drive continuous progress.

INTECO’s Smart Electrode Controller (ISEC) was developed to meet modern furnace operation requirements especially Electric Arc Furnaces and Ladle Furnaces. Designed to control different arc operations, the ISEC can also be applied to other types of electric furnaces for non-ferrous metals, ferro-alloys and even slag heating. The ISEC is based on a state-of-the-art embedded controller that allows high sampling rates and precise computations/calculations of all electric/power values in real time. For flexible operation and fast diagnostics, a modern web-based visualization system is integrated. It offers direct access to advanced information such as working points, control stability, arc lengths, and energy input. Moreover, the ISEC comes with advanced features such as automatic dip testing, automatic valve scaling, adaptive set point control, and a fuzzy logic based foaming slag manager. Standard interfaces such as PROFINET, PROFIBUS or Ethernet/IP facilitate simple integration in new or retrofit projects.

IMAS-PA-EAF provides advanced top-down process guidance through dynamic or static treatment planning and integrated optimization tools. Process supervision is massively improved by the cockpit view and integrated real-time process models. IMAS provides instant real-time information and alerts, based on which the operators can control and steer the process just-in-time. The heat-based data recording stores sensor data, including complex information such as video streams, allowing observation of real-time data for quality assurance and process improvement.

INTECO’s Process Analysis System (IPAS-EAF) directly measures hot and dusty gases and therefore opens new ways to monitor and control the steel making process. The infrared system helps to maintain plant availability, saves energy and helps to protect the environment. Designed for the application in the ultra-harsh environment of an EAF, it provides real-time, in-situ, simultaneous measurement of temperature, CO, CO2, and. The integrated flow measurement system is a single channel solution, which works according to a patented correlation principle. The system is also capable of measuring flow by the flight time of unique signal patterns created by particles contained in the gas. As the principle is time-based, it is accurate and drift-free over the entire lifespan. It seamlessly integrates and enhances the function of the EAF meltdown model.

The INTECO spray cooling master (ISCM) is an automatic state-based cooling optimization to cool down electrodes by air-mist to extend the service life of electrodes. The integrated filter system includes an automatic backwash function to clean the filters automatically and an instrumented pipe assembly to check the pressure and temperature.

The slag detection system controls the amount of pour-over slag in the ladle. The tapping process is monitored by a thermographic (IR) camera. The brightness depends on composition, surface properties and temperature. Even if steel and slag temperature are similar, differences in composition and surface properties allow the system to distinguish between them. The camera is housed in a water-cooled enclosure that is equipped with purged compressed air. This set-up continuously monitors the tapping area with a special detection software that controls the amount of slag until the pre-set alert levels are reached. The software records the entire tapping process for further analysis from start till end.

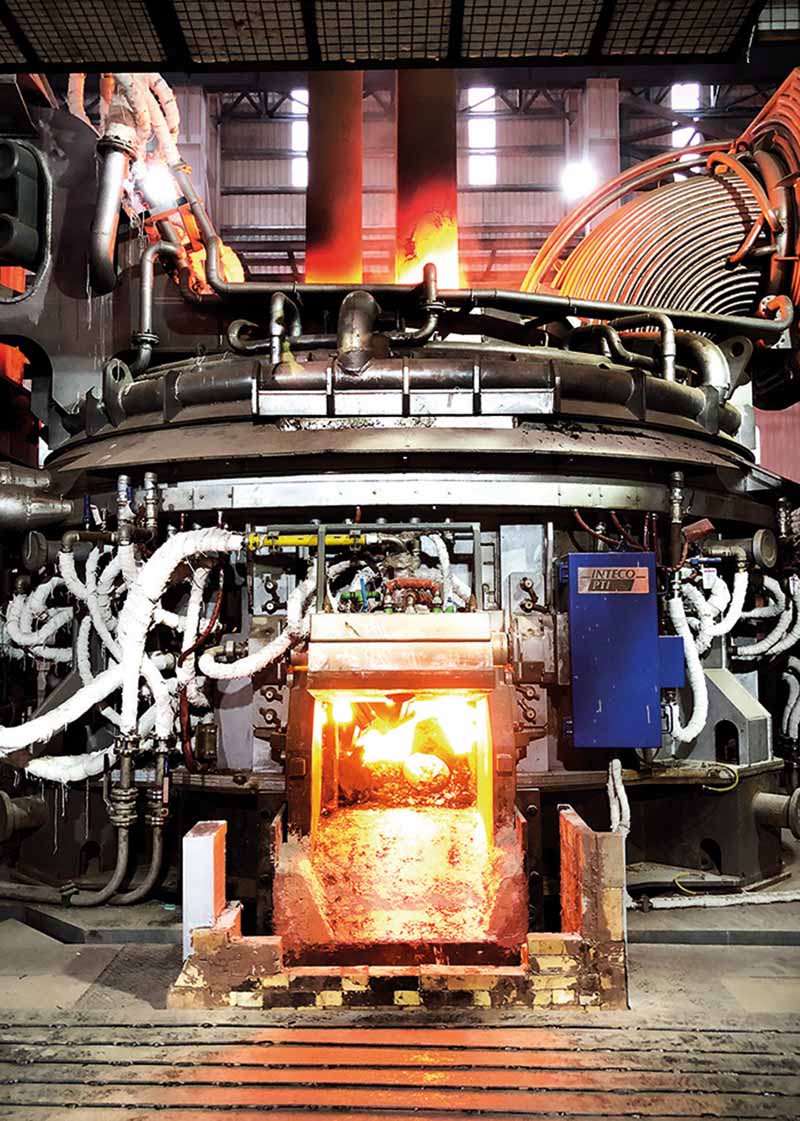

The automatic tapping system (ITAP) automatically lifts the electrode columns to the tapping position as soon as an operator triggers it. Controlled EAF inclination helps to maintain a defined tapping speed, which is the parameter that drives the function and automatically considers the refractory lifetime. After tapping is completed, the EAF can automatically return to a horizontal or deslagging position. If required, a high-resolution (HD) camera can be installed in a water-cooled jacket to provide a video stream to the control room, allowing operators to monitor the tapping process directly.

Our burner and injection control package ensures safe and optimal energy input for a stable and reproduceable melting process. The optional rule-based energy optimization provides an additional control loop enhancing the dynamic power profile with a fuzzy logic engine to finetune furnace set points for minimum electrode consumption, refractory wear, and energy usage. This type of optimization allows to switch directly between production needs such as maximum melt-down performance or minimal operation costs. Moreover, it perfectly integrates with INTECO’s EAF meltdown model and INTECO’s Smart Electrode Control (ISEC).

The EAF Meltdown Model is designed to optimize the electric power profile and electric arc furnace operation by monitoring and predicting the thermal and metallurgical evolution of the heat state. It helps with predictive control, operator assistance, online process optimization, understanding the underlying physical processes, and estimating parameters that cannot be measured directly. It achieves this by detailed modelling of the furnace’s different control volumes including liquid, solid, and gaseous phases. The non-linear model makes it possible to represent complex interrelated phenomena, including the estimation of the visibility of the electric arc and arc efficiency for melting and heating as well as physical modelling principles such as mass and energy balances. It tracks the temperatures, total masses and masses of individual components in both the solid and liquid phases of steel and slag within the furnace.

PROJECTS

Gloria Material Technology

TianMa

Bastug Metallurgy

Metal Ravne

Grupo Frisa