MELT SHOPS

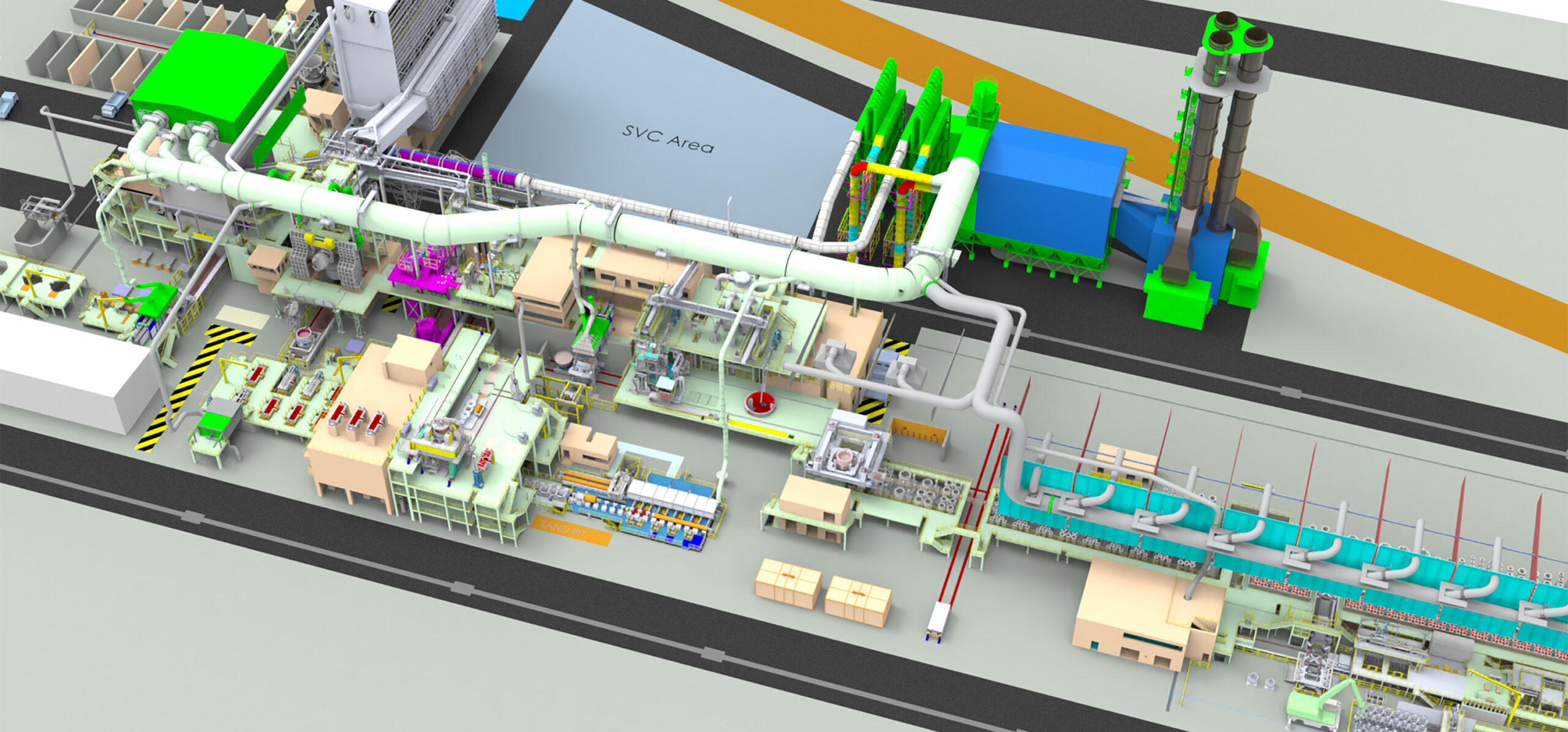

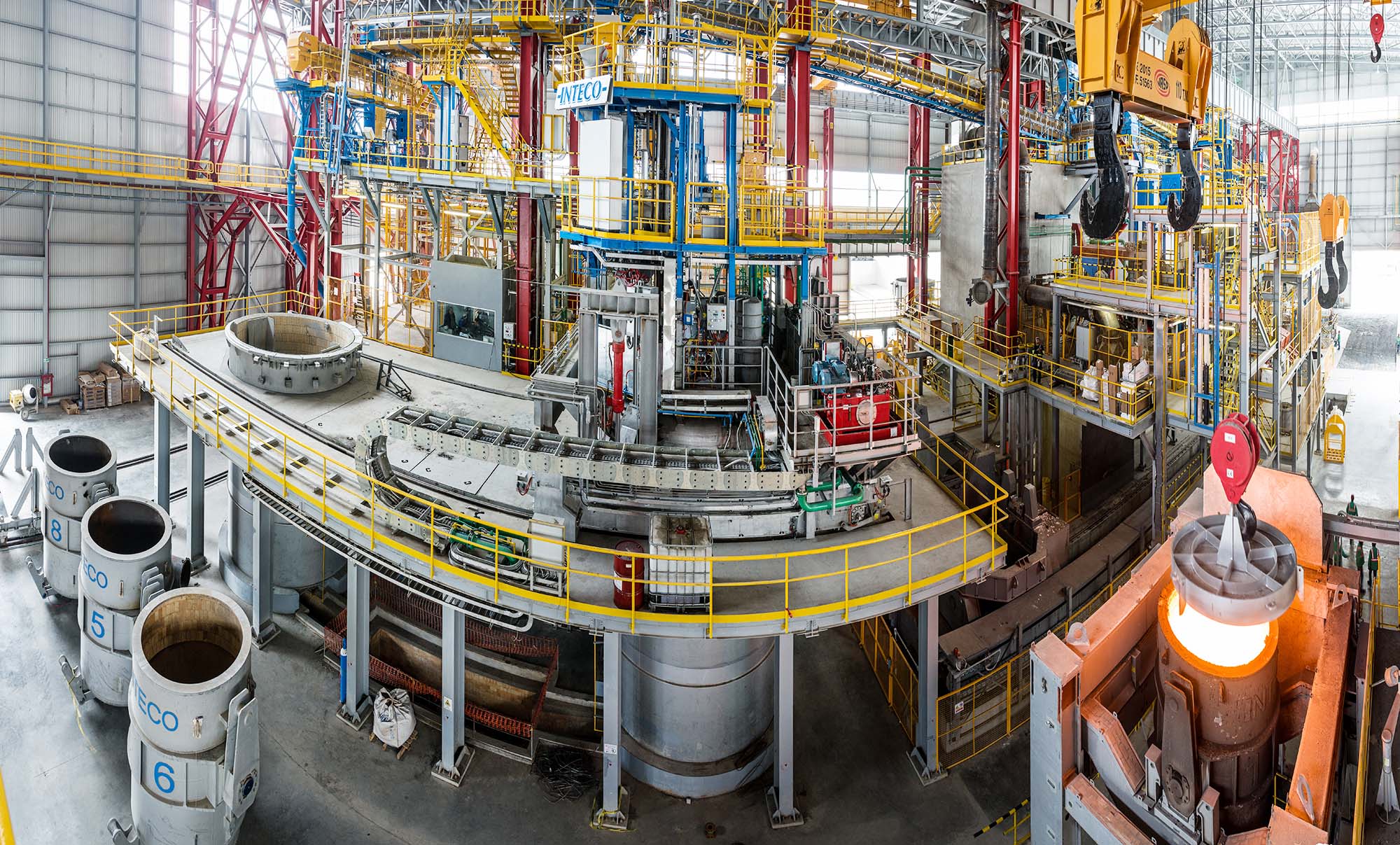

INTECO has installed the majority of complete melt shops for special steel production, which have been realized worldwide over the last two decades. Our reference plants range from mini heat sizes of 5t to supersizes exceeding 150t. The production capabilities are virtually unlimited, including stainless steel, high-alloyed steel, and super alloys.

Melting is typically performed by INTECO’s electric arc furnace, however, induction furnaces are used in special cases. For steel refining, INTECO offers the full range of required plants, including ladle furnaces and various vacuum degassing units (DETEM, VD/VOD, RH).

Finally, a variety of casting facilities, from conventional ingot casting to advanced solutions like INTECO’s Segment Caster or the fully automated Advanced Teeming System, ensure an outstanding quality of the final product.

Electric Arc Furnace

AOD Converter

(Twin) Ladle Furnace

VD/VOD unit

Segment Caster

Conventional ingot casting area

Advanced Teeming System

Dedusting system

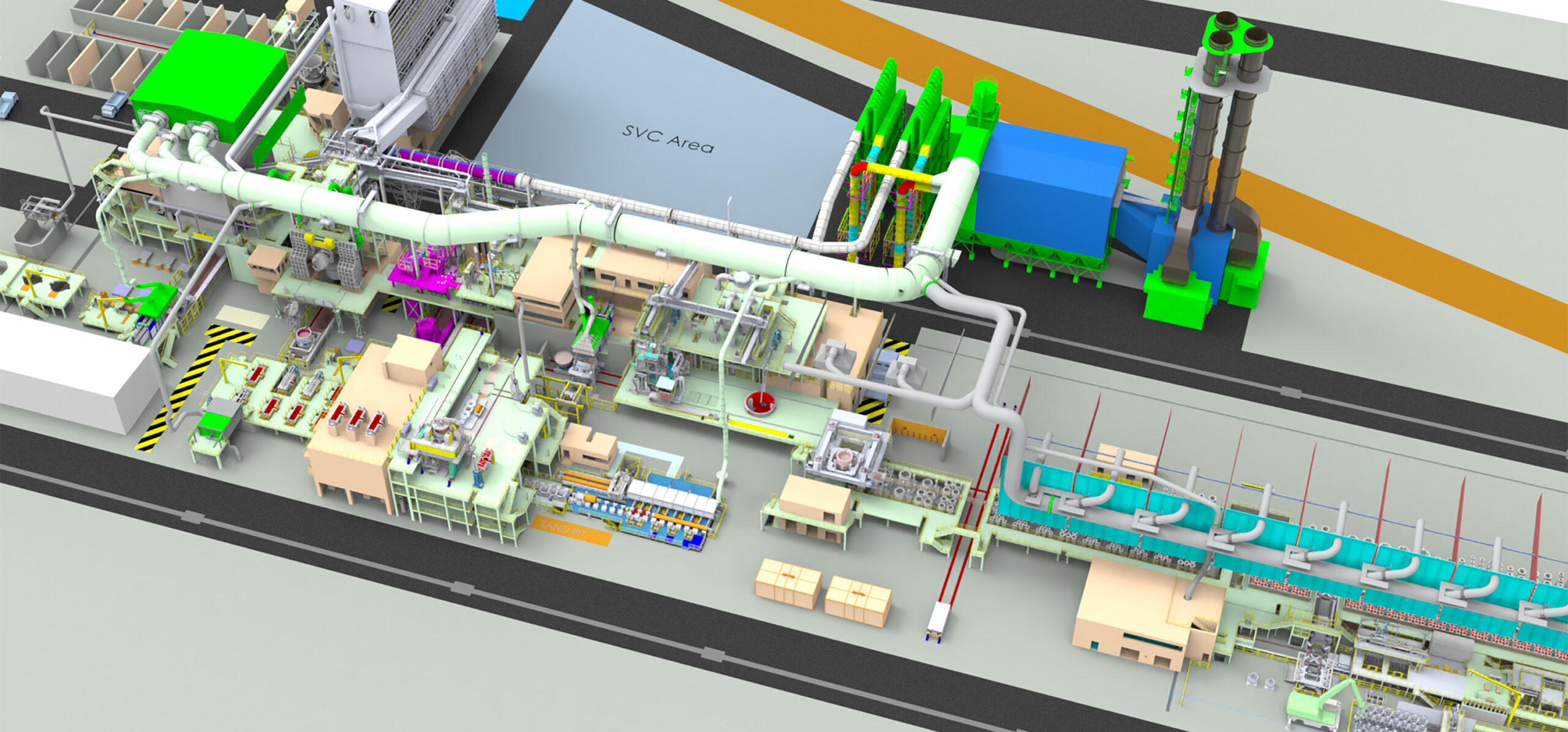

INTECO has installed the majority of complete melt shops for special steel production, which have been realized worldwide over the last two decades. Our reference plants range from mini heat sizes of 5t to supersizes exceeding 150t. The production capabilities are virtually unlimited, including stainless steel, high-alloyed steel, and super alloys.

Melting is typically performed by INTECO’s electric arc furnace, however, induction furnaces are used in special cases. For steel refining, INTECO offers the full range of required plants, including ladle furnaces and various vacuum degassing units (DETEM, VD/VOD, RH).

Finally, a variety of casting facilities, from conventional ingot casting to advanced solutions like INTECO’s Segment Caster or the fully automated Advanced Teeming System, ensure an outstanding quality of the final product.

Electric Arc Furnace

AOD Converter

(Twin) Ladle Furnace

VD/VOD unit

Segment Caster

Conventional ingot casting area

Advanced Teeming System

Dedusting system

INTECO has installed the majority of complete melt shops for special steel production, which have been realized worldwide over the last two decades. Our reference plants range from mini heat sizes of 5t to supersizes exceeding 150t. The production capabilities are virtually unlimited, including stainless steel, high-alloyed steel, and super alloys.

Melting is typically performed by INTECO’s electric arc furnace, however, induction furnaces are used in special cases. For steel refining, INTECO offers the full range of required plants, including ladle furnaces and various vacuum degassing units (DETEM, VD/VOD, RH).

Finally, a variety of casting facilities, from conventional ingot casting to advanced solutions like INTECO’s Segment Caster or the fully automated Advanced Teeming System, ensure an outstanding quality of the final product.

PROJECTS

Gloria Material Technology

system, ingot casting car & Advanced Teeming System

NPO

Grupo Frisa

Taewoong Special Steel

ingot casting & vacuum stream degassing plant

voestalpine Stahl Donawitz