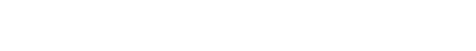

AUTOMATIC GAS COUPLING SYSTEM

The INTECO automatic gas coupling system is a quick, safe, reliable and maintenance friendly automatic connection device for stirring gas supply to the ladle. Its purpose is to connect the stirring gas supply automatically by placing the ladle on the ladle stand or transfer car. In case your stirring gas supply is still done manually, INTECO’s solution is indispensable to guarantee highest possible operator safety.

- Function & design

- Non-return valve

- Application

- Our technology – your advantage

The system’s compact and sturdy design is meant to withstand the rough operating conditions in the steel plant environment.

The automatic gas coupling system consists of a lower part which is installed on the ladle transfer car, VD/VOD-vessel etc. and an upper part which is mounted on each ladle. By placing the ladle on its station via crane, the upper and lower part are pressed together, and the stirring gas supply is connected automatically. Fixation is done by tailor-made templates to ensure a perfect positioning of both sections. The stirring gas is supplied via a separate gas control unit, from which flexible hoses are connected to the lower part. A hose reel or a festoon system allows stirring even during ladle car movement.

INTECO’s automatic gas coupling system is designed to compensate for possible misalignments of the upper and lower part up to 85mm in the X-, Y-axis plane. This ensures tightness during operation even despite a misalignment, which is a typical case in steel plants.

Sometimes more than the most common solution – the vertical gas coupling system – is necessary to fulfil the customer’s requirements. Limited space and less ladle stroke are a well-known and recurring challenge. INTECO is your perfect partner to meet this challenge. Together we can analyze the situation and find a solution tailored to your individual needs as of gas supply capacity and the number of porous plugs, which can be connected. Our system suits simply any application.

INTECO’s non-return valve (NRV-600) is designed to withstand the rough conditions in a steel plant environment. It withstands temperatures of up to 600°C. The compact, robust, and high-temperature-resistant design enables an easy installation on the ladle and has virtually no leakage due to utilization of metallic-tight sealings. A filter is integrated in the non-return valve, which avoids unwanted impurities. The check valve can be used to connect both INTECO’s automatic gas coupling system as well as a manual one. Thus, in the very unlikely event of an automatic coupling failure, there is still the possibility to couple manually.

A – INTECO non-return valve

B – INTECO’s automatic Gas Coupling System

C – Manual system

- Teeming ladle during tapping from electric arc furnace and converter

- Within the deslagging station VD/VOD (up to 600 °C in the vacuum vessel)

- RH plants

- Ladle furnace

- Ladle stirring station

- Ladle turret

The automatic gas coupling system offers numerous advantages. Like the name already indicates, it is a fully automatic system, hence, it is perfect for all steel plants as safety awareness and protecting the operating personnel from hazards is more important than ever before. Manually connecting and disconnecting of the stirring gas supply at the ladle exposes the operator to an unacceptable risk. Unexpected steel and slag splashes or an over boiling of the molten steel can happen unexpectedly any time. Furthermore, staying in the crane manipulation area is very dangerous.

The system is independent of any hydraulic or pneumatic system or electrical power. As soon as the ladle with the upper part is placed into the treatment position the spring installed in the housing of the lower coupling part is compressed. Only the force of the compressed spring acts on the lower part as the ladle weight is taken up by the ladle seats of the transfer car or ladle stand.

Application in high temperature areas? No problem! The metallic sealing system withstands ambient temperatures of up to 600°C (as in VOD vessels). Moreover, the benefits even show off in the long run. The absence of rubber seals avoids the exchange of the coupling unit prematurely due to burning or damage of the seal. Therefore, low maintenance is guaranteed by use of wear-resistant materials as well as simple and sturdy design with good access to all components.

Benefits at a glance:

- Improvement of operator safety

- Precise stirring during the whole process due to automatic control

- No periodical maintenance or service required

- No periodical exchange of wear parts

- Metallic sealing system, thus low maintenance efforts

- High temperature resistance (VD/VOD proven, up to 600°C)

PROJECTS

Nucor Hertford

Ternium Siderar

Confidential Customer

Optimus Steel